Hygiene is becoming more and more important not only in particularly hygiene-sensitive areas. In order to fulfil the associated disinfection requirements, Hako scrubber-driers can be equipped with additional tools – both for large-area and more detailed applications. Hako’s machines therefore not only provide excellent cleaning results but also make a valuable contribution to preventing and containing the transmission of pathogens via contaminated surfaces.

The benefits of cleaning and disinfecting with Hako:

- Only one machine for cleaning and disinfecting

- Easy handling

- Solutions for all areas: automated disinfection via the machine’s brush unit (standard equipment) and the spray bar or manual disinfection via the hand spray wand

- Improved cleanliness and increased hygiene

- Flexible application

- Hygienically clean machine: with Hako-AntiBac® , our innovative feature equipping the tanks with antibacterial properties; plus easy access to all components enabling quick and reliable disinfection with the hand spray wand

- Even more efficient application with Hako-AquaControl

Suitable solutions for all areas

Floors, walls, door handles or grips: All objects and surfaces that come into physical contact with people are potential sources of infection where germs, fungus and bacteria are easily transmitted from one person to another, even without any personal contact. As each application area poses different demands on cleaning and disinfection tasks, Hako offers optimally adapted options to apply disinfectants to objects and surfaces– up to a solution providing cleaning and disinfecting in a single working step.

Walk-behind scrubber-driers – disinfection via the chemical container or the solution tank

For small to medium-sized areas, e.g. in schools, hospitals and nursery homes or spas/ saunas and sports halls: The disinfection solution is applied by means of the chemical container and the on-board dosing system via the brush head or the hand spray wand. Alternatively, the disinfectants can be mixed with water in the solution tank.

1 Hand spray wand

2 Brush unit for cleaning tasks

Walk-behind scrubber-driers – disinfection via the chemical container or the solution tank

After the cleaning task is completed, the solution tank is used for the disinfectant/water mix, which is applied to the surface directly via the disc brush head, the spray bar or the hand spray wand. Suitable for disinfecting large areas, e.g. in the logistics and food processing sectors

1 Solution tank containing disinfectants

2 Brush unit for disinfection tasks

3 Spray bar for disinfection tasks

4 Hand spray wand for disinfection tasks

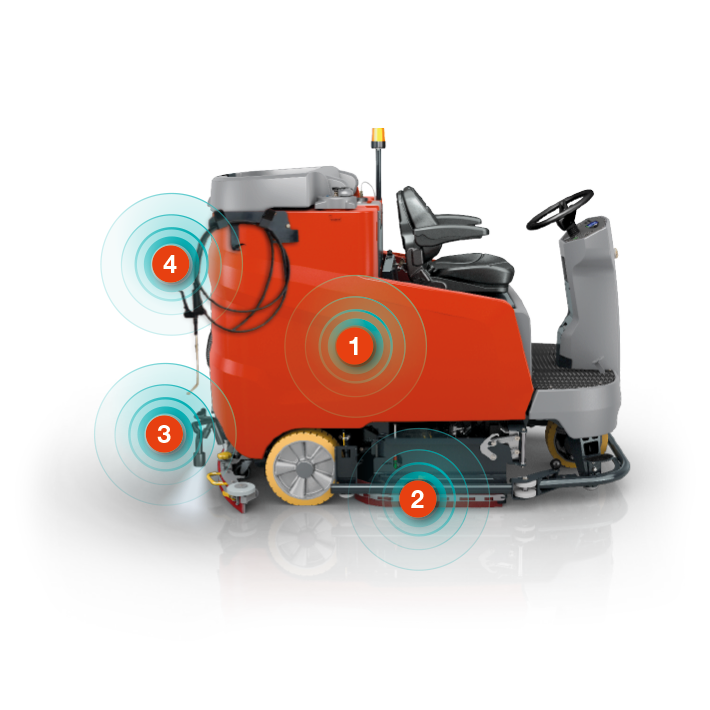

Ride-on scrubber-driers – chemical container with on-board dosing system for concentrated disinfectants and cleaning chemicals

Use of the chemical container and the on-board dosing system to apply the water/disinfectant solution. Advantage: easy alternating between cleaning and disinfecting because the water in the solution tank remains neutral. Suitable for supermarkets, car dealerships etc.

1 Solution tank/ clean water

2 Brush unit for cleaning or disinfection tasks

3 Spray bar for disinfection tasks

4 Hand spray wand for disinfection tasks

5 Chemical container for the disinfectant solution or cleaning chemicals

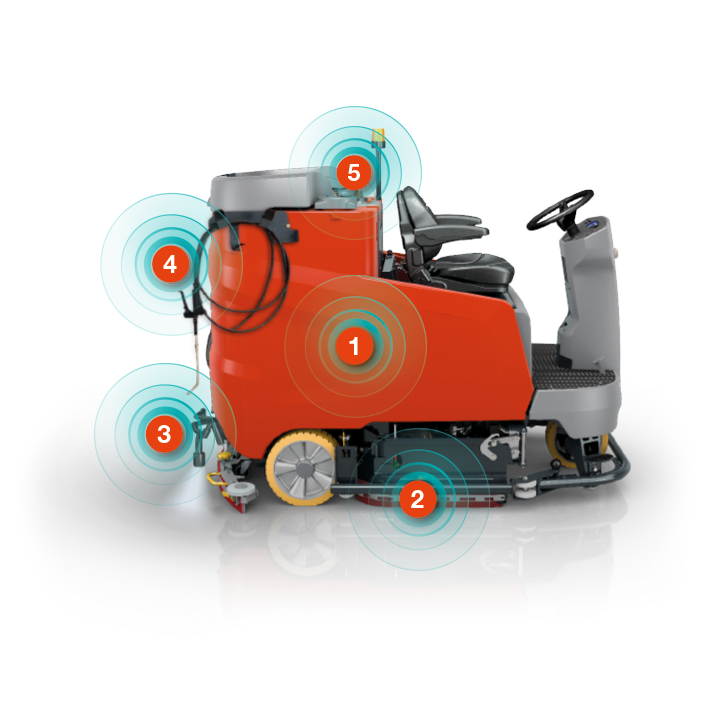

Ride-on scrubber-driers – cleaning and disinfecting in a single working step

Cleaning and disinfecting large areas at the same time: The disinfectant solution is applied by means of the front-mounted container via the spray bar or the hand spray wand, while the brush head takes care of the cleaning job. Suitable for production plants, public areas and facilities etc.

1 Solution tank/ clean water

2 Brush unit for cleaning tasks

3 Spray bar for disinfection tasks

4 Hand spray wand for disinfection tasks

5 Chemical container for the cleaning detergent solution

6 Front-mounted container for the disinfectant solution

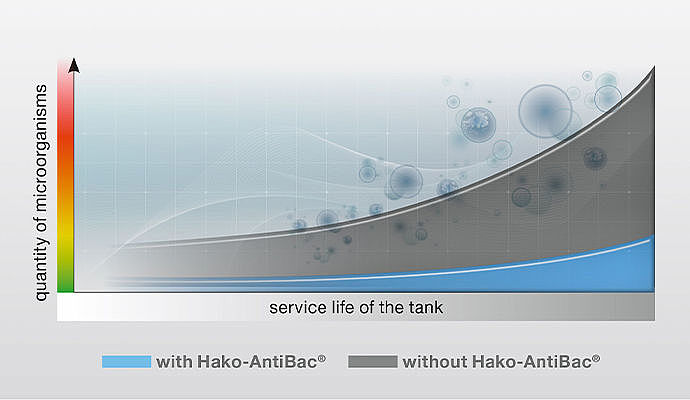

Hako-AntiBac®: protects both people and cleaning equipment

Cleaning Technology made by Hako can not only be used to disinfect floors and surfaces, but also to improve the hygiene of the machine itself: for example by equipping the solution and recovery tank with Hako-AntiBac®. This innovative antibacterial feature protects the plastic material of the tanks and reduces the development of fungal and bacterial growth, which makes it much easier to meet even the highest hygiene standards with a minimum of cleaning effort.

Other benefits provided by Hako-AntiBac®:

- Improved hygiene and reduced odour development

- Protects the health and safety of employees due to less contact with microorganisms

- Protects the environment and reduces costs due to the lower consumption of tank cleaning disinfectants

- Extends the service life of the tank

- Standard equipment with Scrubmaster B45 CLH, available as an option for all other models

Hako-AquaControl: for even more efficient applications

Increased hygiene standards require even more efficient cleaning – in the same working hours. Hako-AquaControl saves up to 50 % of water and thus reduces breaks for emptying and refilling the tanks.

Other benefits provided by Hako-AquaControl:

- Automatically stops the water supply when the machine is standing still

- Precise dosing at all times

- AquaStop® water-stop rings ensure that the cleaning detergent solution remains longer in places requiring thorough cleaning.

Best results – safe working!

During the cleaning process, the brushes of scrubber-driers have constant floor contact – and therefore also get in contact with various microorganisms on the floor. In order to protect the machine operator’s health and safety, Hako provides important information on how to safely handle the machine when carrying out daily maintenance tasks: